Lean Six Sigma Program

Six Sigma is a data-driven methodology aimed at improving business processes by reducing variability and eliminating defects. Developed by Motorola in the 1980s and popularized by companies like General Electric, Six Sigma provides a structured framework for continuous improvement, emphasizing quality and efficiency.

Core principle of Six Sigma

lloCustomer Focus: Understanding and meeting customer needs is at the heart of Six Sigma. Every improvement initiative begins with identifying what is important to the customer.

Data-Driven Decision Making: Six Sigma relies on statistical analysis to identify root causes of problems and to measure improvements. This data-driven approach ensures that decisions are based on facts rather than assumptions

Process Improvement: Six Sigma aims to improve processes by identifying and eliminating causes of defects and variability. This results in more consistent and predictable process outcomes.

Employee Involvement: Successful Six Sigma implementation requires the involvement of employees at all levels. Training and empowering employees to contribute to process improvements is a key aspect of Six Sigma.

- Sustainable Results: Six Sigma focuses on achieving long-term, sustainable improvements. This is achieved by continuously monitoring processes and maintaining the gains made through improvement efforts.

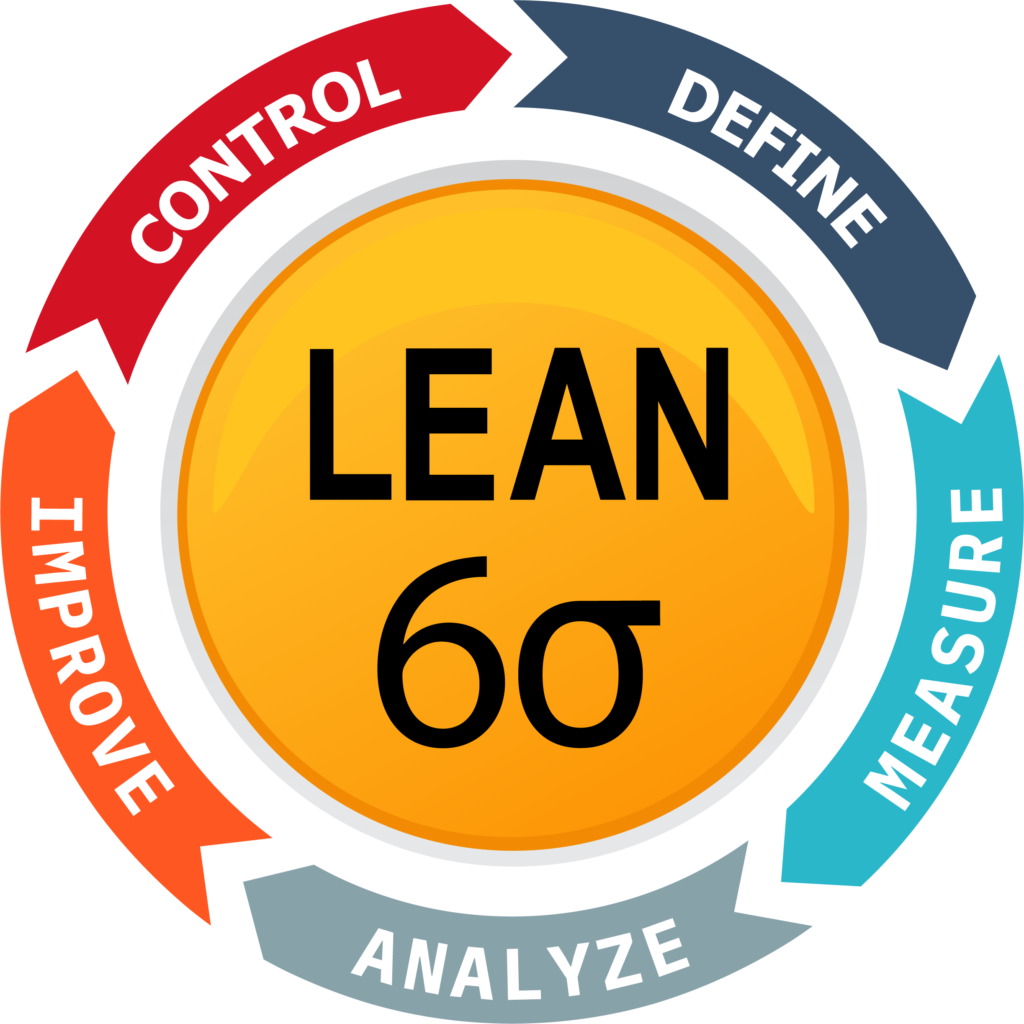

The DMAIC process

The DMAIC process is the core methodology used in Six Sigma for process improvement. It consists of five phases:

Define: Identify the problem, define project goals, and outline the scope of the improvement initiative.

Measure: Collect data on current processes and performance to establish a baseline for improvement.

Analyze: Use statistical tools to identify the root causes of defects and process variability.

Improve: Develop and implement solutions to address root causes and improve process performance.

Control: Monitor the improved process to ensure that gains are maintained and improvements are sustained over time.

Benefits of Six Sigma

- Enhanced Quality: By reducing defects and variability, Six Sigma ensures higher quality products and services.

- Increased Efficiency: Streamlined processes lead to faster cycle times and lower costs.

- Improved Customer Satisfaction: Consistently meeting customer expectations results in greater satisfaction and loyalty.

- Employee Engagement: Involving employees in improvement initiatives fosters a culture of continuous improvement and empowerment.

- Financial Performance: Reduced waste and improved efficiency translate into significant cost savings and profitability.

Leannovate’s Approach to Six Sigma

At Leannovate, we integrate Six Sigma principles into our training and consulting services to help organizations achieve operational excellence. Our team of certified Six Sigma professionals works closely with your organization to tailor Six Sigma projects that align with your business objectives and deliver measurable results.