Why Not Five Sigma is Better Than Six Sigma?

Many of my students often ask, “Why isn’t five sigma better than six sigma?” It’s a common question that can be quite perplexing. To address this, let’s delve into the basics of the bell curve and standard deviations, and understand why six sigma is preferred.

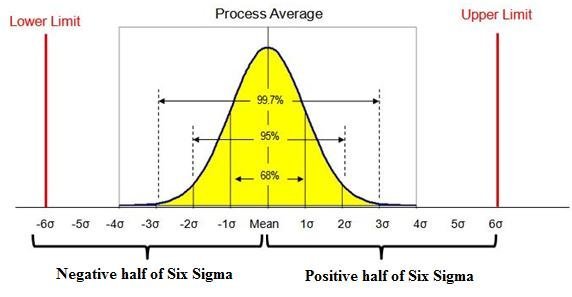

Firstly, we need to understand that the specification limits (upper and lower) are fixed. These limits are set based on customer requirements or industry standards and do not change based on the data we collect. Your bell curve and standard deviation can change depending on the data, but the specification limits remain constant.

When your process data is well-centered around the target, the standard deviation (a measure of variability) will be smaller. This means your process is producing consistent results that are close to the desired target. In such cases, within the fixed upper and lower specification limits, there will be more standard deviations (or sigmas) because the data is tightly packed around the center line.

Conversely, if your process data is poor and deviates significantly from the target, the standard deviation will be larger. This means your process is producing more variability and is less consistent. As a result, within the same fixed specification limits, there will be fewer standard deviations, because the data points are spread out and farther from the center line.

The key takeaway here is that Six Sigma aims for a process where the data is tightly packed around the target, resulting in more standard deviations (six) within the specification limits. This indicates a highly consistent and reliable process with minimal variation, which is why six sigma is preferred over five sigma. It ensures higher quality and fewer defects, meeting stringent customer and industry standards.